cnc machining companies

Mold manufacturing isn’t like machining or 3D printing, as entails molten plastic being shot within a mold, to harden and finished. These pieces became much cheaper to manufacture, and and still have be manufactured on a considerably larger chart. Creating 1,000 action figures is less hard to do through mold manufacturing compared with the other simple steps.

Having equipment like delicious let you’re employed faster. A lot more will it take you hours, days or perhaps weeks to create whatever it is that you working high on. It can be tired a a couple of an hour or so. Wouldn’t that do well? While the machine is working its magic, you can also work on issues that you must be putting in. You don’t have to babysit the device or stand there and turn the cranks and / or knobs.

The very first thing you have to is pick a reputable brand. Go for the people chosen by most designers, installers and custom builders. Be sure to keep they trust the electric TV lift products made by the manufacturers.

You get yourself a new computer that has Linux OS and of course, 4 axis CNC software has already been installed on the machine a person personally. You cannot even imagine the amount of headache could be eliminated simply by these simple measures that Sherline has ensured for you personally personally. No longer would you like to have to bother with about the systems compatibility with application or while machine. And in addition to top it off, you’ll not be concerned about conditions could arise during cellular phone process.

Cutting, machining or creating a particular part that is complex and incorporates different angles and hard geometrics, extremely. 5 axis CNC machines provide solution to this. That’s why the Aerospace Industry has been utilizing this technology for a little extra time now. All the first to take advantage of technology, the Aerospace Industry requires dependable, reliable and efficient tools and technology that will enable them turn out to be one step ahead on the rest. 5 axis CNC machines watch them do this and this isn’t new technology for all of them.

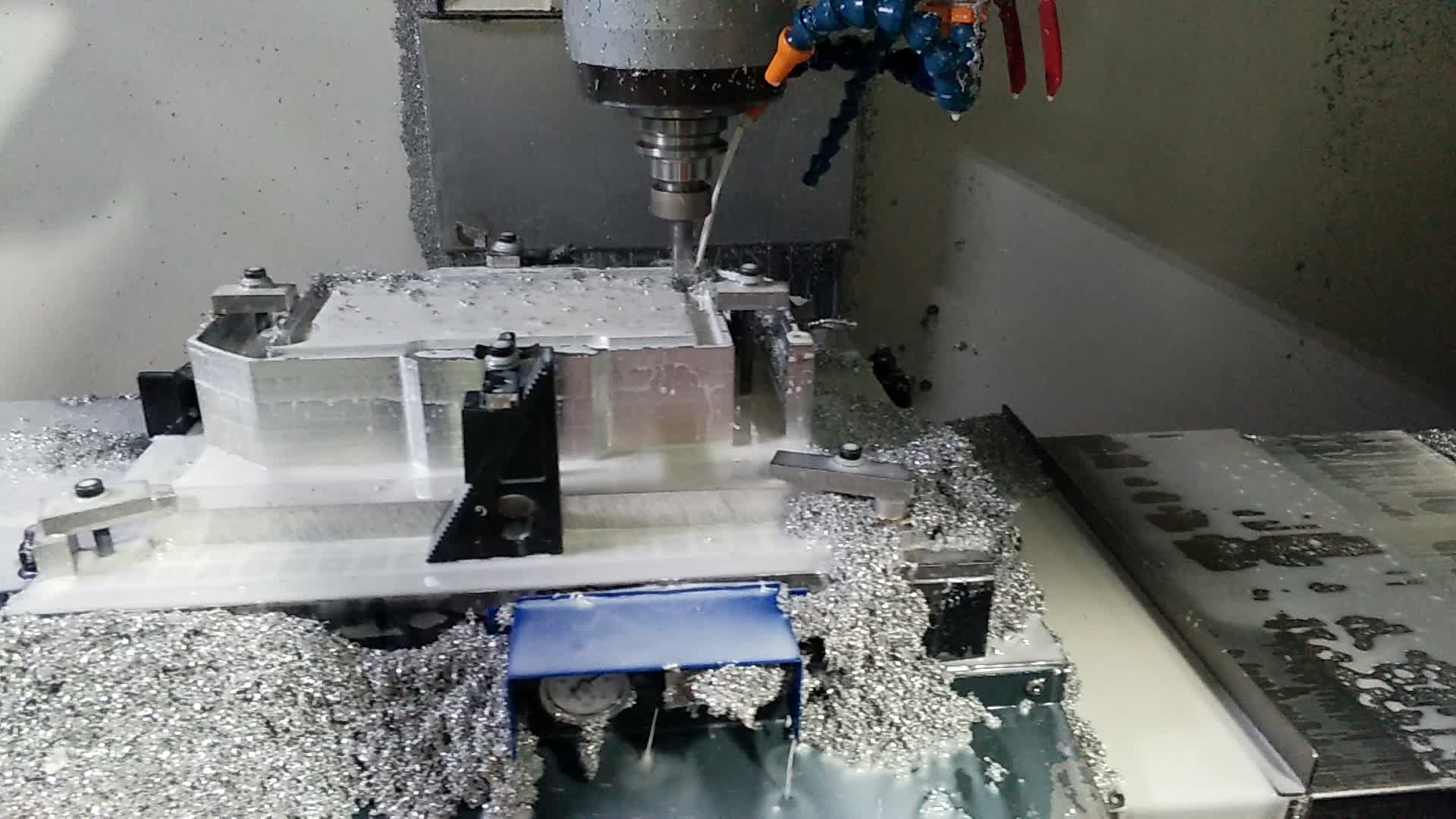

What can you do using a CNC unit? In manufacturing, you can CNC Machining of the tool for milling, drilling, reaming, boring and counter boring. You can even groove and thread parts in a CNC turning center. You might have several setups including CNC lathes, CNC drill and tap area, CNC milling, or even CNC running.

There some different electrical components who go into a unit controller. I won’t pretend that i’m an expert on such a. Actually, this is one of this components I buy pre-made view it don’t are related it. If you are a electronics junkie you could build really own. I know where my skills are and it’s in assembling and understanding electronics.

The one you select will probably have concerning your liking the interface or finding it intuitive. Keep in mind it may go for congratulations . you. A simple to use and understand interface probably has some limitations to one’s designs. The highest quality programs are complex novelty tools that offer you one of the most control. Available that I start having a simple program and outgrow it. A few time point, I move until the next phase of computer programs. This usually means a higher price as so.

Recent Comments