Welcome to the world of valves and controls, where precision, reliability, and efficiency are paramount. Valves play a crucial role in various industries, serving as the gatekeepers of fluid and gas flow within systems. In this comprehensive guide, we will delve into the intricacies of valve control, exploring how these components work together to ensure seamless operations in industrial, institutional, and government settings. Valworx, an ISO 9001-certified supplier, stands at the forefront of providing high-quality actuated valves and controls that meet the diverse needs of our discerning clientele. With a commitment to excellence, we offer a wide range of automated valve assemblies that are meticulously built, rigorously tested, and promptly shipped to our markets, enabling businesses to enhance their processes with optimal efficiency.

Understanding Valve Basics

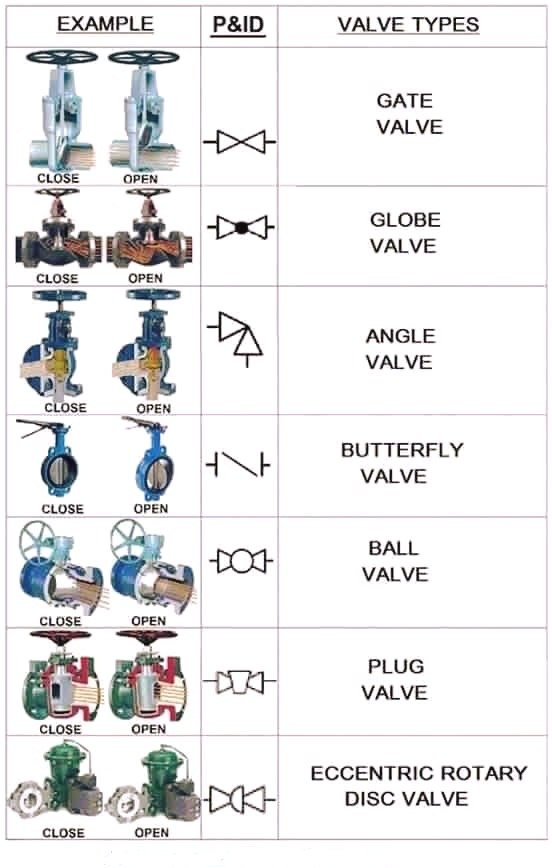

Valves are essential components in various industries, facilitating the control of flow, pressure, and direction within piping systems. Valves come in different types, such as ball valves, gate valves, and butterfly valves, each serving specific functions based on the application requirements.

Motorized butterfly valve for remote control

Proper selection of valves is crucial to ensure optimal performance and reliability of any system. Factors to consider include the type of fluid or gas being controlled, operating pressure and temperature, flow rate, as well as the desired level of control precision. Valworx offers a wide range of high-quality valves and controls to meet diverse industry needs.

Valworx’s expertise in providing ISO 9001-certified actuated valves and controls sets them apart as a trusted supplier for industrial, institutional, and government markets. With a focus on quick turnarounds, quality testing, and same-day shipping, Valworx ensures that customers receive reliable valve solutions promptly to support their operations.

Benefits of Actuated Valves

Actuated valves provide enhanced efficiency and accuracy in controlling flow. With automated functionality, these valves can be remotely operated, reducing the need for manual adjustments. This results in improved responsiveness and precise regulation of flow rates, contributing to smoother operations and optimized system performance.

Incorporating actuated valves enhances safety by minimizing the risk of human error. The automated nature of these valves reduces the potential for misconfigurations or faults during operation. By streamlining the control process, actuated valves help prevent accidents and ensure consistent, reliable performance in diverse industrial applications.

Another key advantage of actuated valves is their adaptability to various environments and conditions. Whether in extreme temperatures or corrosive settings, actuated valves maintain their functionality and durability, providing a long-lasting solution for controlling fluid flow. Their versatility makes them ideal for a wide range of industries, offering a reliable and efficient solution for diverse valve control needs.

Applications of Automated Valve Assemblies

Automated valve assemblies play a crucial role in various industries, facilitating the regulation of fluid flow in complex systems. From wastewater treatment plants to energy production facilities, these assemblies provide efficient control over the movement of liquids and gases. Their precision and reliability make them indispensable in ensuring optimal performance and safety in industrial processes.

One key application of automated valve assemblies is in the oil and gas industry, where they are used to regulate the flow of oil, gas, and other fluids in pipelines and refineries. By automating the valve control process, operators can remotely manage critical operations, improve operational efficiency, and minimize the risk of leaks or spills. This level of automation enhances overall productivity and reduces maintenance costs in this demanding sector.

Moreover, automated valve assemblies find significant use in the pharmaceutical and food processing industries, where maintaining strict quality standards is essential. These assemblies help control the flow of liquids and gases with precision, ensuring compliance with safety regulations and maintaining product integrity. By incorporating automated valve assemblies into their processes, manufacturers can achieve consistent product quality, operational efficiency, and regulatory compliance.